Features

FEATURES

Features

FEATURES

HORIZONTAL AND VERTICAL SHAFT ALIGMENT

The built-in electronic inclinometer keeps you from having to adjust levels and indicates at all times the shaft rotation angle. LA Blue uses an extremely precise and linear detector therefore does not require any correction. The chain universal brackets are very easy to put on and take what makes fast work.

COMPUTER OPTIONS

The LABlue software runs under Windows operating systems (10, 8, 7, Vista, and XP).

Depending on the kind of environment you can choose between a standard computer or a rugged computer designed for industrial use (It complies with IP65 protection and MIL-STD-810G).

The LABlue is delivered with the computer and ready for use.

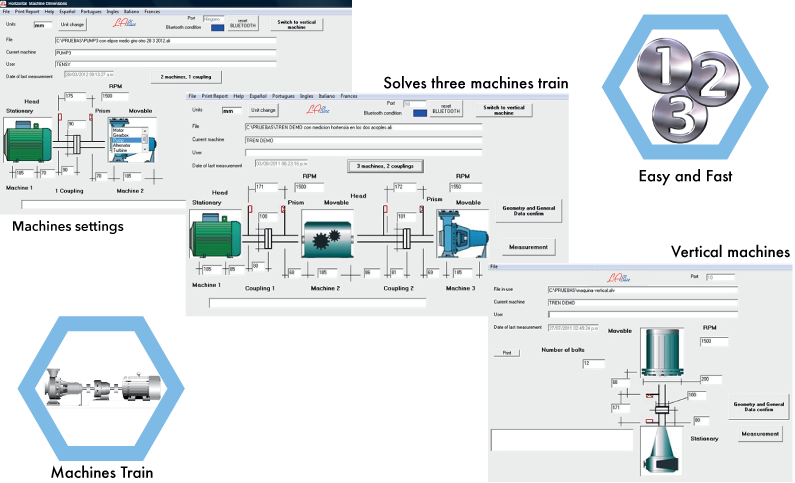

ALLOWS PRECISE AND QUICK MACHINE VERIFICATION AND CORRECTION

OF SHAFT ALIGNMENT CONDITION IN ONLY 3 STEPS

STEP 1: Simply choose whether to work with two machines or a train of machines, select the machine type and enter measures such as distances, coupling's diameter and rotational speed (RPM) in the blank boxes. You can start filling in any box as the order does not matter. To guide you throughout all steps contextual help will appear in a box at the bottom of the screen indicating the input values in each case.

STEP 2: Measurement is simple and easily performed by rotating the shafts from any position and in any sense. You can choose between different measuring modes as continuous, 0369 or multipoint. In case you are unable to make a full shaft turn you can use the restricted rotation mode. Extension Mode feature allows you to continue measuring even if the machines have a gross misalignment.

STEP 3: Once the measurement is completed results will appear in graphical and numerical values of offset and gap in the vertical and horizontal views corresponding to the values in the coupling. The offset is the distance between two lines in the plane of transmission of the coupling, while the gap is the angle between the two shafts multiplied by the diameter of the coupling. These values take into account any correction made by Targets or Thermal Growth if such options are active. The results include the vertical and horizontal position of the machine foots to enable the correction.

LABlue FEATURES

Easy-to-use form. You do not need to be a specialist in alignment.

Show alignment condition in a matter of minutes

Take alignment readings with only 3 steps

Precise laser shafts alignment system for horizontal and vertical machines

Machine train alignment of up to 3 elements

Measurement in machines with restricted shaft rotation

Wireless communication BLUETOOTH (R)

Transmitter-receiver head dimension reduced

Small size Prisma (85mm x 60mm x 48mm)

Freedom from backlash effects

High definition color graphics

Convenient operation thanks to user guidance in display

Soft foot checking

Rechargeable battery with charging status indicator. More than 10hs battery life

Intelligent power management for longer battery life

Compact chain-type bracket set

ABS case (dust-sand proof, IP 67, watertight, extreme weather, military Spec-4150J, airline safe ATA 300)

Hard-copy alignment reports in any printer set as default on your Windows network

Save and recall of machine geometry makes the job easier and saves time

Save of machine alignments allows records

Automatic electronic inclinometer no more levels to use!

Tolerance selection in built-in tables

Coupling Targets and Thermal growth

Live Move for horizontal correction

Detector Extending Mode